Production & Facility Optimization Solutions to Eliminate Emissions

IJACK's product lines include mutiphase transfer pumps (XFER), vapor recovery units (VRU), hydraulic (EGAS) and beam-mounted (DGAS) gas compressors, artificial lift (UNO), and more.

Since 2010, we've proudly helped energy companies produce oil and gas in the most reliable, automated, green and cost-effective manner. With over 1,000 units operating in North America, we build strong relationships with our customers and strive to provide the best after-sale service and support (you'll be surprised how little service is actually required).

IJACK Automation

IJACK products are fully automated so you can set it and forget it. Our remote control and monitoring system RCOM™ measures, reports, and automatically adjusts to reach your operators' setpoints. If something unexpected happens, RCOM will let you know with SMS, email, or phone call alerts (free of charge) so you can take action either remotely or on-site.

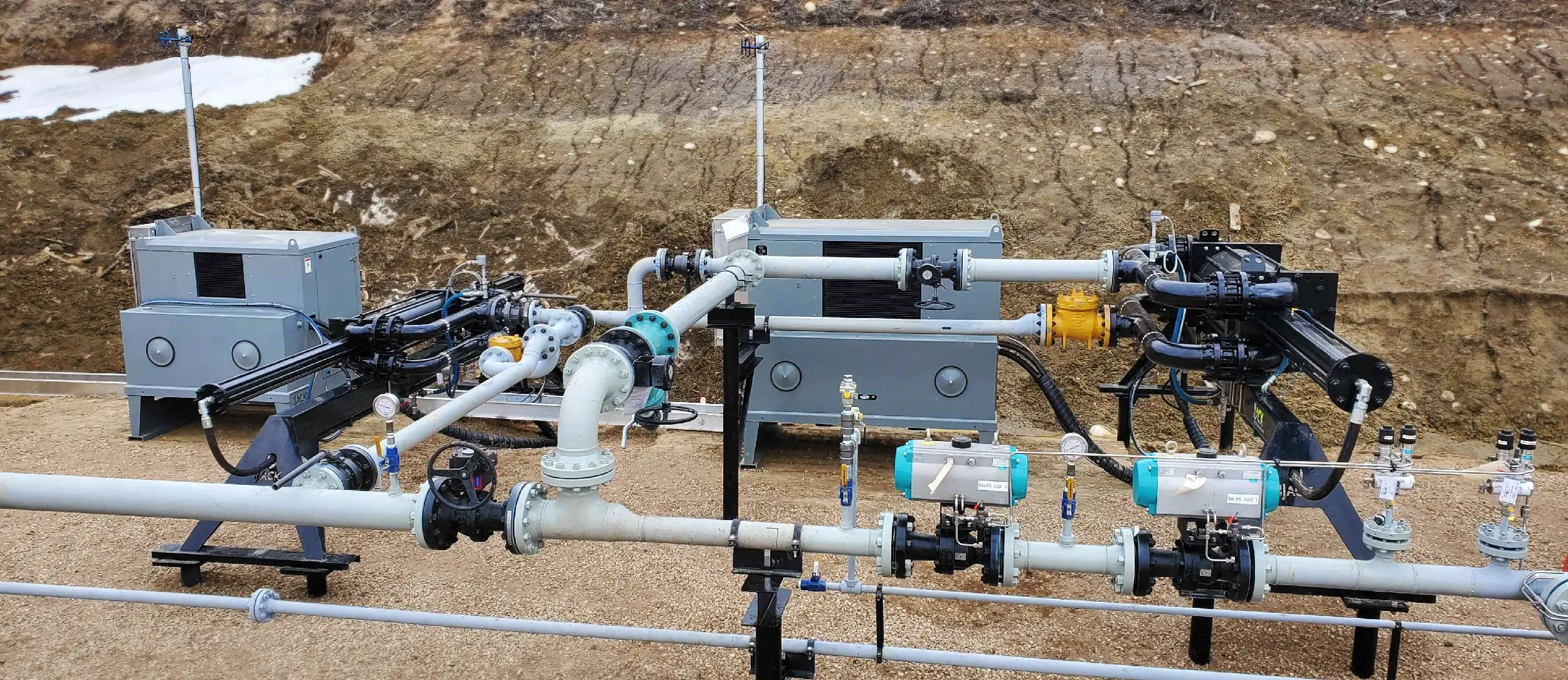

XFER™ Multiphase Pump

100% liquid to 100% gas allows for any potential gas liquid ratio (GLR)

IJACK is the inventor of the original, patented, dual-acting reciprocating hydraulic multiphase transfer pump. XFER allows operator to pump oil, gas, water, solids, emulsions, or anything else your well throws at you. Install it to lower your line, wellhead, and casing pressures to optimize production.

Eliminate entire separation facilities and save millions

No need to separate the gas from the oil and pump them separately. IJACK customers have saved millions on expensive facilities, simultaneously reducing operating costs while greening their operations.

VRU™ Vapor Recovery Unit

Zero Emissions

IJACK's closed loop, scrubberless, AI controlled, reciprocating VRU technology helps meet your ESG initiatives.

Don't vent it, sell it!

Capture vapors and natural gas liquids from storage tanks, vapor recovery towers, or vessels, and put them in your gas sales line.

EGAS™ Wet Casing Gas Compressor

Improve Well IPR.

EGAS allows the producer to tie-in and reduce casing pressure in multiple wells and reach a broad range of volumes and intake pressures.

Reduce Emissions.

IJACK's closed loop, scrubberless, AI controled, compression technology helps reduce your operation's carbon footprint.

DGAS™ Beam-Mounted Compressor

Relieve Pressure. Improve Performance.

Compress up to 10 decs/d (350 mcf/d)

Same purpose as EGAS, but it bolts onto your existing conventional pumpjack.

Simple Installation

Secure it to your pumpjack in less than two hours with no welding.

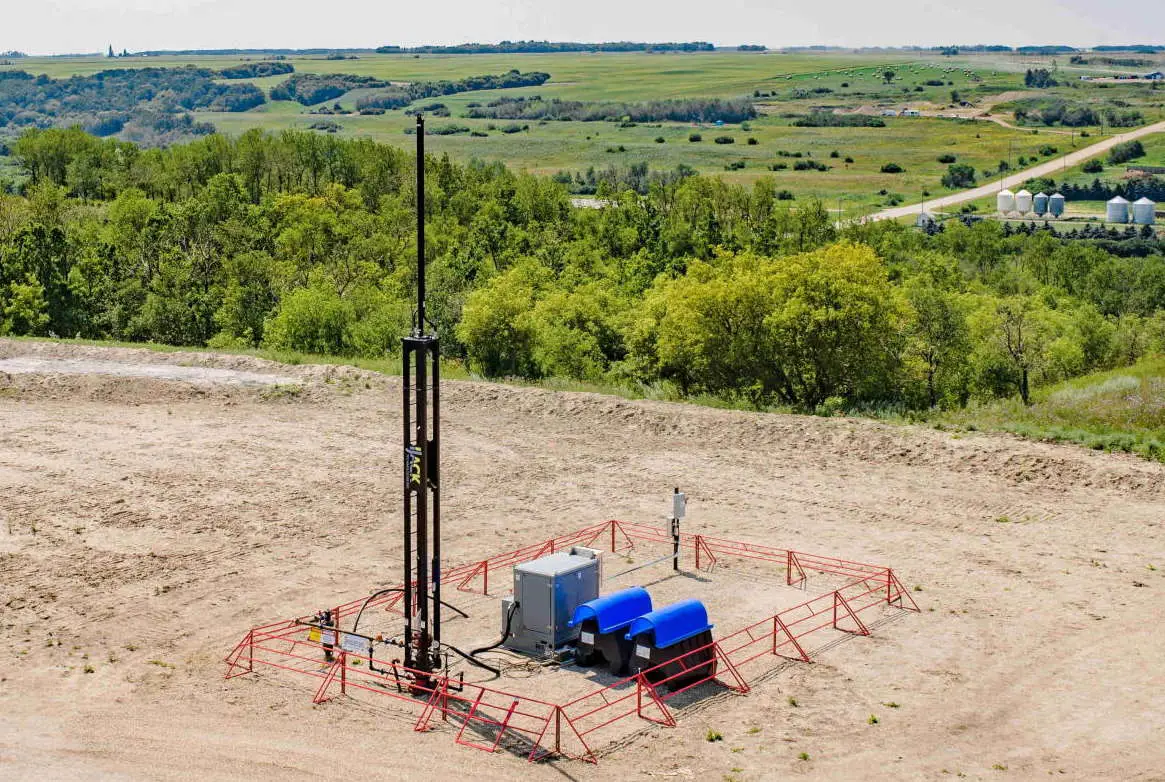

UNO™ Hydraulic Pumpjack

Automatic Production Optimization

- Maintain constant fillage

- Reduce downhole wear

- Automatic pump-off control

- Adapt to changing downhole conditions

- Machine learning surface card alerts

Fast and Easy Installation

Up and running in less than two hours

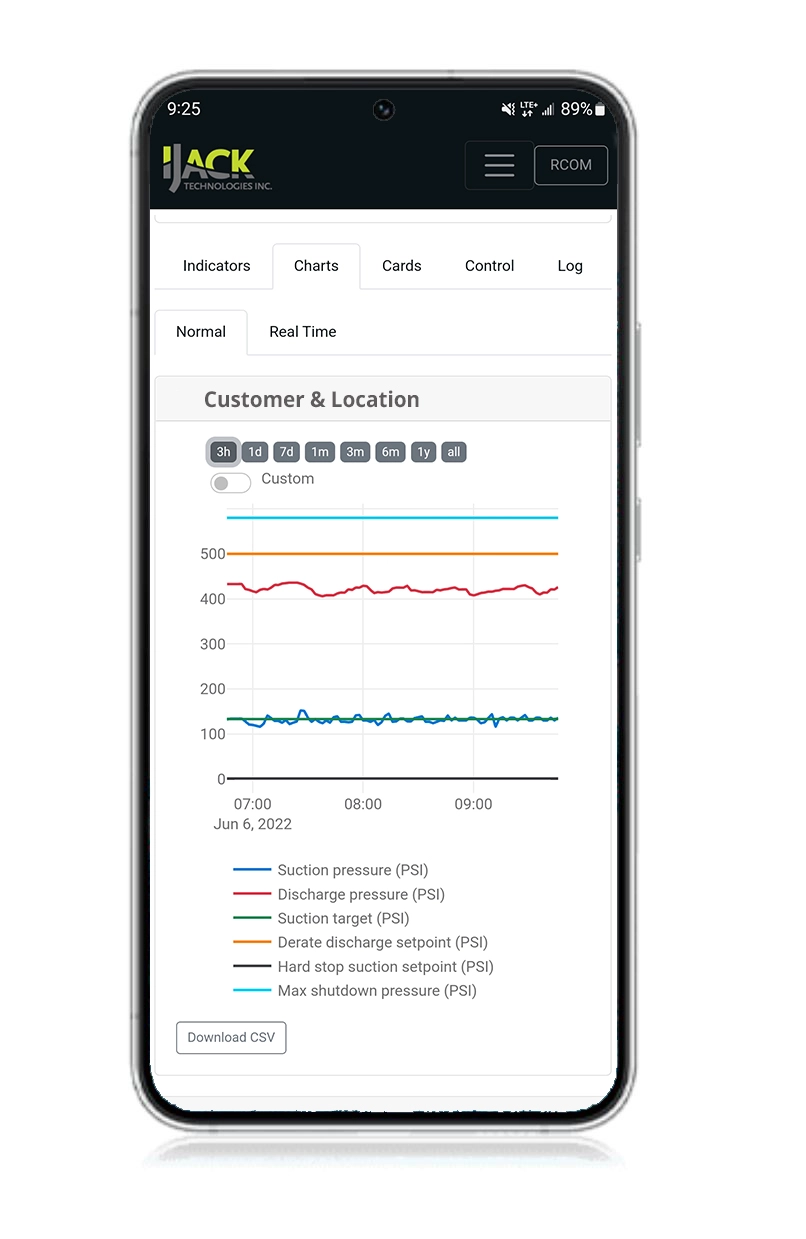

RCOM™ Remote Control and Monitoring

IJACK developed its own user-friendly, installable web app that comes free-of-charge with any product you buy (excluding DGAS). All you have to do is register.

IJACK RCOM is a web-based application that allows you to monitor and control your IJACK equipment from anywhere in the world. Best of all, it's free of charge with any product you buy (excluding DGAS).

All you have to do is register.

IJACK Solutions

IJACK has a solution for your production and facility optimization challenges

| Challenge | Solutions |

|---|---|

| Eliminate / reduce emissions, venting and flaring | XFER, EGAS, VRU, DGAS |

| Lower casing, wellhead, and flowline pressures simultaneously to allow more production inflow from the formation | XFER |

| Pump multiphase (oil, water, gas and solids) in emulsion or stratified forms from the wellhead directly to a battery with no additional equipment in-between | |

| Lower pipeline pressures to allow lower pressure wells to access the pipeline and keep pipelines under maximum operating pressure | |

| Transfer emulsions (oil, gas, water and solids) to and between facilities | |

| Eliminate hydrates and methanol use by lowering pipeline pressure under the hydrate curve | |

| Flowback / unload thermal wells faster and with less equipment | |

| Reduce / eliminate liquid loading on free flowing wells and boost the production to a facility | |

| Replace building new satellite or underutilized facilities which are expensive to build, maintain, operate and abandon | |

| Pump slurries and solids (e.g. sand and paraffins), in your production stream | |

| Avoid pumps cavitating, gas-locking, or hydro-locking | |

| Pump/compress emulsions over long distances and mountainous terrain to a facility | |

| Optimize artificial lift by extending downhole equipment run life, reducing workover frequencies, lowering stuffing box pressures, reducing PCP torque, increasing plunger lift cycle rates and reducing injection pressures and volumes for gas lift | |

| Handle wet casing gas and associated fluids without blow cases or scrubbers | EGAS |

| Lower sales gas flowline pressures | |

| Lower casing pressure, increase production / inflow from formation | EGAS, DGAS |

| Capture gas from treater separators and discharge into gas or emulsion flowlines | |

| Lower tank / tower pressures, remove and recover vapor gases and condensates | VRU |

| Intensify pressure in reinjection / water flooding operations and extend injection areas by increasing pressure | BOOST |

| Handle high inlet pressures / transfer fluids with or without gas | |

| Avoid acidizing and determine if injection resistance is due to scale build up or formation natural back pressure | |

| Avoid building new / expanding current fluid injection facilities | |

| Pumpjack with variable stroke speed and length changes with a push of a button - top and bottom stroke delays | UNO |

| Fully automated remote-controlled pumpjack to optimize production | |

| Pumpjack set up in 2 hours with minimal crew | |

| The benefits of a hydraulic pump jack and casing gas compressor in one unit | UNOGAS |

| Control and monitor equipment from anywhere at anytime | RCOM |

IJACK ADDS A NATURAL GAS ENGINE OPTION

IJACK customers now have the option to run their units using an electric motor or natural gas engine power unit.