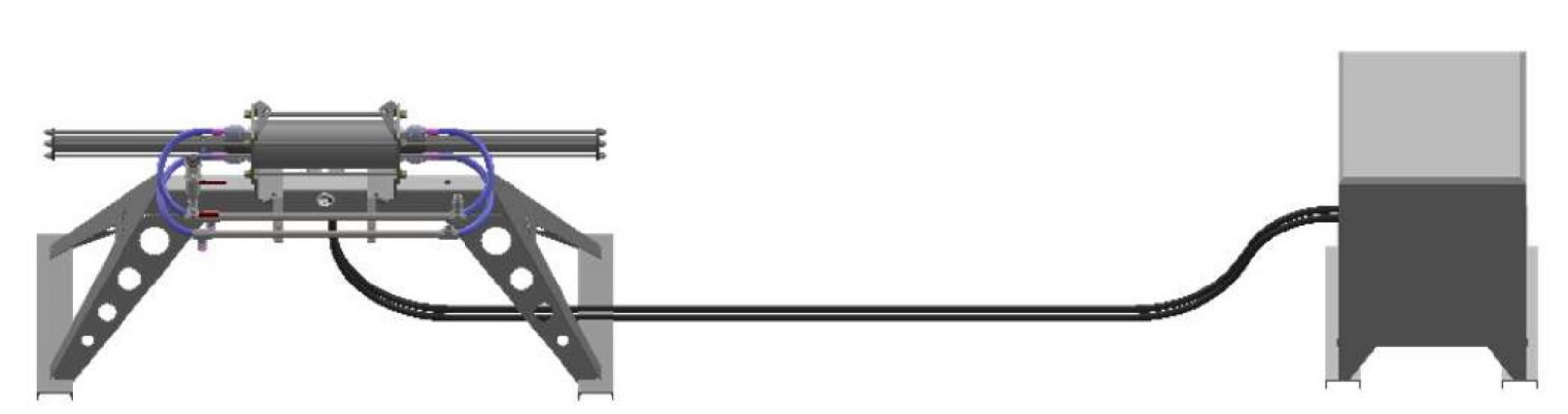

Boost™ High Pressure Water Injection Booster Pump

Boost pressure. Produce more oil and gas.

Does you fluid injection system need a high inlet pressure intensifier pump? If so, do you have pressure drop issues with the most remote wells where you need to restore/increase pressure to those locations?

The IJACK BOOST pump can handle high intake pressures and boost the discharges pressures to the required level with pressure differentials up to 2,200 PSI.

By utilizing N50 rods and a SS barrel, you can rely on the BOOST to handle the high corrosive nature of processed water. Options are available for non-corrosive environments.

Keeping you on top of well performance.

No matter where your site is. No matter where you are. You are always in control. IJACK RCOM™ remote control and monitoring shows you precise, comprehensive, up-to-the-minute operating data, historical trends, compression cards, alarm logs and the ability to remotely control your units.

RCOM also includes an alerting system via email, SMS text messages, or phone calls to alert you of any problems such as power outages, or potential problems such as suction pressure spikes, and guide you on steps to be taken. Custom alerts can be created for any metric of interest, and configured from myijack.com.

Armed with this key information, you can analyze data and make the required changes to improve performance, efficiency and profitability.

Learn More About RCOM